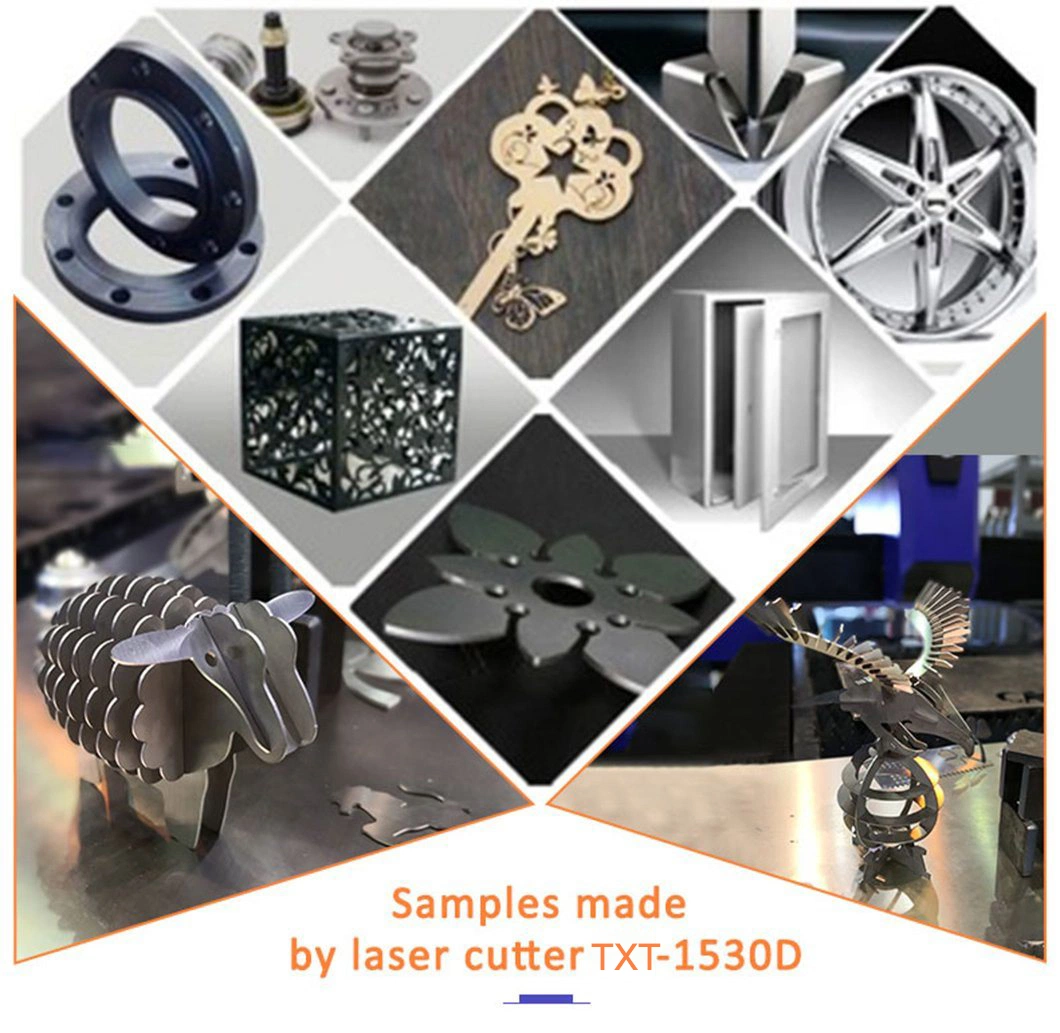

Fiber Laser Cutting Machine Sheet Metal with Laser and Double Exchange Tables Laser Cutting Machine for Carbon Sheet 1500*3000m 1000

Basic Info.

| Model NO. | TXT-QG-1530 |

| Cooling System | Water Cooling |

| Technical Class | Continuous Wave Laser |

| Applicable Material | Metal |

| Structure Type | Gantry Type |

| Laser Classification | Free Electron Laser |

| Laser Technology | Laser Control Fault Cutting |

| Laser Medium | Glass Fiber with Rate-Earth Element |

| Max Cutting Speed | 18m/Min |

| Laser Wavelength | 1070 Nm |

| Laser Output Power | 1000W/1500W/2000W/3000W/4000W |

| Transport Package | Wood Pack by Sea |

| Specification | 11800*4200*2200mm |

| Trademark | TXT LASER |

| Origin | China |

| HS Code | 8456110090 |

Packaging & Delivery

Package Size 1180.00cm * 420.00cm * 220.00cm Package Gross Weight 8000.000kgProduct Description

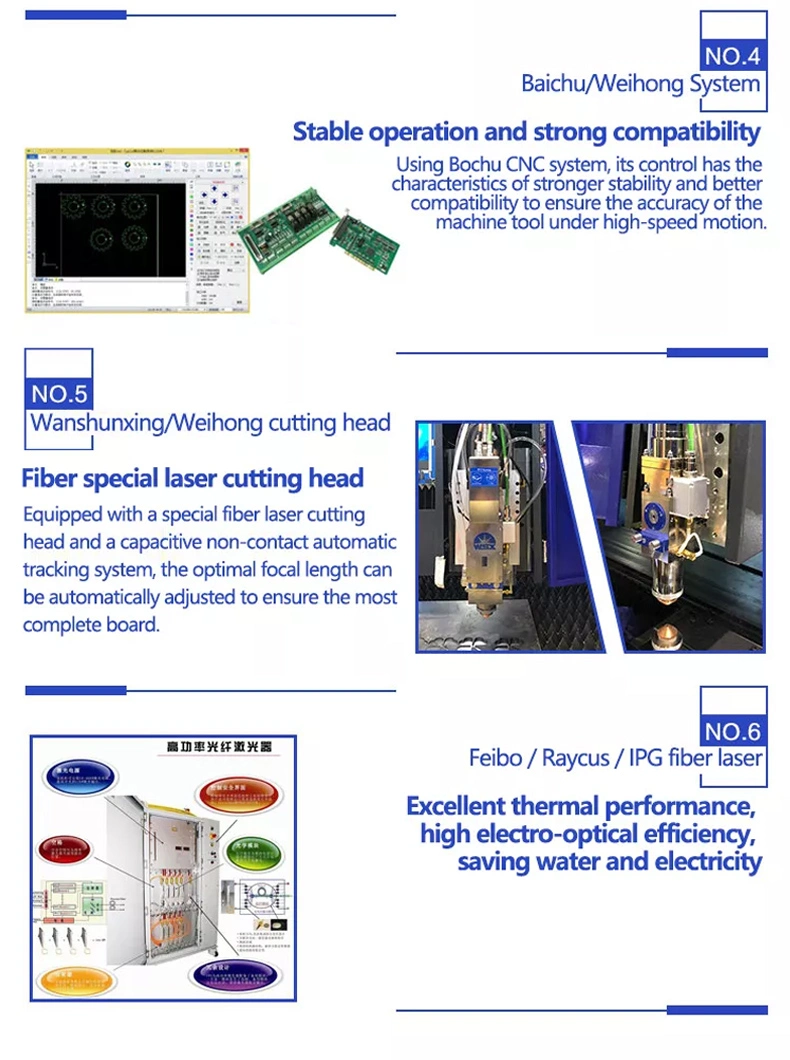

Machine features:1 Adopting all covered frame structure to avoid radiation damage to operators. It is equipped with high-efficiency transmission mechanism such as imported high-precision rack and linear guide. It has good dynamic performance and fast servo response through advanced numerical control system.. It achieves higher cutting efficiency with medium-power fiber laser. 2 Adopting gantry structure, the equipment has high precision, good rigidity and stable operation. The machine tool is equipped with a universal roller device,which is labor-saving and convenient.3 The machine base is made of high-quality 16mm steel plate and pipe welded frame structure. The machine tool is subjected to high temperature annealing treatment, secondary aging treatment and large-scale gantry milling machine precision machining. These design and processing methods ensure the machine has excellent shock resistance, high rigidity and stability.4 With a blanking drawer, you only need to pull out the drawer when cleaning the blank.5 With the automatic focusing cutting head, the optimal focal length can be automatically adjusted to ensure the best cutting effect of the whole board.6 The capacitor non-contact automatic following system ensures that the cutting head and the cutting material have the same height, which avoids material scrapping caused by the height variation problem when the material is not flat.7 Using fiber lasers, the electro-optical conversion efficiency is high, the power consumption during operation can be greatly saved, and the running cost saved; the trimming is less affected by heat, the slit is flat, and generally no secondary processing is required.Product Parameters

| Laser Power | 2000-6000w | Cutting Thickness | Above 10mm |

| The Laser Wavelength | 1070nm±10nm | Aimed and Positioning | Red light |

| Min.line Width | 0.1mm | Power Supply | 380v/50HZ |

| Repeat Position Accuracy | ±0.05mm | Cooling Mode | water cooling |

| Cutting Range | 2000*4000mm | Product Size | 11800×4200×2200mm |

| Running Speed | 120m/min | Transmission Mode | Double Rack |

technical parameter

| order number | name | make a footnote | name | make a footnote |

| 1 | Environmental temperature requirements | 15-45ºC | Maximum cut carbon steel thickness | 80mm |

| 2 | Power grid requirements | AC380V±10%,50Hz | Maximum cut stainless steel thickness | 100mm |

| 3 | Machine tool positioning accuracy | ±0.03mm/m | Maximum cutting aluminum alloy plate thickness | 50mm |

| 4 | Repeat positioning accuracy | ±0.03mm/m | Maximum cutting speed of m / min | 1-55 |

| 5 | acceleration | 1.2G | Edge detection accuracy | ±0.5 |

| 7 | laser power | 20000W | Total power supply protection rating | IPS4 |

| 8 | laser-conversion efficiency | ≥35% | laser wave length | 1068-1080 |

| 9 | Beam mass of the BPP | ≥3.5mm*mrad | Laser power stability | ±2% |

| 10 | Fiber core diameter | 100um | levels of protection | IP54 |

| 11 | Humidity requirements | 10%-80% | Minimum line width | 0.15 mm |

| 12 | Power grounding resistance | Admito 3 ohm | Appearance and color of the complete equipment | Red + white |

| 13 | Foundation amplitude | Less than 50um and less than 0.05g | Equipment motion mode | Bilateral drive |

| 14 | Power consumption of the whole machine | ≤98KW/h | Fluid oxygen consumption / time | thirty yuan /h |

| 15 | Liquid nitrogen consumption / time | fifty yuan /h | Compressed air cost / hour | twenty-five yuan /h |

| 16 | processor | I5 | Solid State Disk | 256GB |

| 17 | internal storage | 28GB | joggle | The USB / DVI / bus |

Operation technology

1: The use of laser special automatic programming nesting software, with automatic programming nesting, layout, word processing, process setting, printing, transmission, import, perforation, microconnection, cutting sequence, optimization of cutting path and optimization of speed and other powerful application functions, It greatly improves the management utilization rate of sheet metal and saves operation time.2: Improve the utilization rate of the plate: it can realize the gap layout of the parts, the embedded layout of the parts, the symmetrical flip layout of the parts, the rotation layout of the parts and avoid the appearance overlap and collision.3: Avoid local overheating (avoid component distortion), and avoid local overheating through the cutting path processing of regions and partitions.4: Sharp Angle processing: inside/outside Angle processing, can be automatically identified and set.5: Powerful word processing function: entity word can be processed into hollow words.6: Common-side line segment cutting optimizes cutting efficiency and improves sheet metal utilization.7: Support marking and small hole marking.8: Support pre-perforation and rest layout and rest cutting.9: The system displays letters, digits, and symbols in Chinese and English.10: Support common edge cutting optimization path.11: The system automatically applies different cutting processes according to different material and thickness set by the user, including: compensation method (compensation radius), punching method (punching time), cutting power, tool guide method, microconnection, bridge and other parameters.12: Pre-punch: According to the set conditions to complete the pre-punch function.13: Deal with sheet metal modules and quantity of material waste processing and utilization management.14: Power off continued cutting memory continued cutting function, differential function, automatic edge patrol function, leapfrog cutting function.

As a global enterprise TXT laser is committed to providing better laser cutting solutions to customers aroud the world insisting on quality focusing on service and continuous core technological innovation and R&D.

The product are serialized and diverslfied to meet more needs of customers the product quality is excellent and durable ,creating maximum value for customers,timely after-sales service,professional and efficient handing of proble,free sample cutting,free customer training,high volume exhibition support.Pre-sale serviceThe supplier provides the demander with a variety of production process solutions, technical consultation of laser equipment, sample samples, equipment selection, technology and price consultation and other pre-sales services.In-sale serviceIn accordance with the contract, the supplier shall safely transport the equipment to the installation site designated by the Demander within the prescribed time free of charge, and send technical service engineers to install the equipment on site. When the installation and debugging conditions are basically met, the technical service engineer will install and debug the machine within 2-5 days for users to use, to ensure that the installation and debugging site environment is neat, clean and orderly; At the same time, provide relevant technical training to customers' designated personnel.After-sales service1) Main training content 1) Operation procedure training for switching machine; 2) Training on the meaning of panel and control parameters and the range of parameter selection;3) Cutting control software operation training; 4) Basic cleaning and maintenance of the machine;5) Common hardware failure processing; 6) Software, hardware and process problems and treatment methods that should be paid attention to during operation;7) The trainee of the demander is 1-2; 8) Installation training time is not less than 5 days;9) In addition, it also provides technical support for the demander's products.

Q: How about after-sales service?

A: 1. We can provide free training in our company. 2. If u need, our engineers are available to service machinery overseas. But u need pay the tickets and hotel fees for our engineersQ: How about the warranty?

A: 2-year warranty for engraving machine,3-year warranty for laser machine.Life time maintenance

Q: What should I do when I have some problems or questions?

A: Pls don't hesitate to contact us, we will reply u ASAP

Q: How about the quality?

A: Before we pack each machine, we will test it first. If machine has problem in your place, our worker will take responsible for his mistake. And we will solve your problem

Q: Which is the most suitable model machine for me?

A: Pls tell us your materials, thickness, size and business industries.We will select the machine model that is right for you.